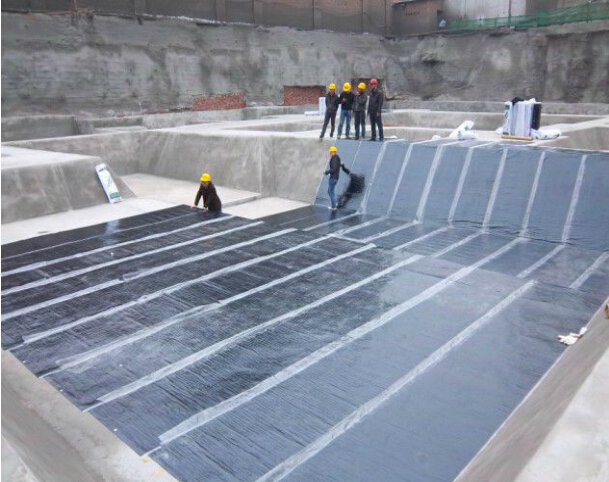

HDPE Membrane Application

HDPE Membrane Application

Introduction

HDPE is also used for cell liners in subtitle D sanitary landfills, wherein large sheets of HDPE are either extrusion or wedge welded to form a homogeneous chemical-resistant barrier, with the intention of preventing the pollution of soil and groundwater by the liquid constituents of solid waste. HDPE is preferred by the pyrotechnics trade for mortars over steel or PVC tubes, being more durable and safer. HDPE tends to rip or tear in a malfunction instead of shattering and becoming shrapnel like the other materials.

Milk jugs and other hollow goods manufactured through blow molding are the most important application area for HDPE, accounting for one-third of worldwide production, or more than 8 million tons. In addition to being recycled using conventional processes, HDPE can also be processed by recycle bots into filament for 3-D printers via distributed recycling.[6] There is some evidence that this form of recycling is less energy intensive than conventional recycling, which can involve a large embodied energy for transportation.

Above all, China, where beverage bottles made from HDPE were first imported in 2005, is a growing market for rigid HDPE packaging, as a result of its improving standard of living. In India and other highly populated, emerging nations, infrastructure expansion includes the deployment of pipes and cable insulation made from HDPE. The material has benefited from discussions about possible health and environmental problems caused by PVC and Polycarbonate associated Biphenyl A, as well as its advantages over glass, metal, and cardboard.

Why Choose Our Service?

Expert People

Certified Company

Quality Work

24/7 Support